Sand casting is a widely used manufacturing process for producing metal parts and components of various sizes and complexities.

It’s a versatile method that can be applied to create everything from small, intricate pieces to large, heavy-duty machinery components.

China has emerged as a significant hub for sand casting, offering a vast array of manufacturers and suppliers.

However, navigating this market can be complex due to its sheer size and diversity.

In this guide, we’ll explore the ins and outs of buying sand castings from China manufacturers to help you make informed decisions and secure high-quality products.

Understanding Sand Casting

Before delving into the specifics of buying sand castings from China, it’s essential to have a basic understanding of the sand casting process.

Sand casting is a traditional and highly adaptable method used to create metal parts. It involves the following key steps:

- Pattern Making: A pattern, typically made of wood or metal, is created to replicate the shape of the desired part.

- Molding: A mold is made by packing sand around the pattern. This mold is then removed, leaving a cavity that matches the part’s shape.

- Melting and Pouring: The chosen metal (usually aluminum, iron, or steel) is melted in a furnace and poured into the mold cavity.

- Cooling and Solidification: The metal in the mold cavity cools and solidifies, taking on the shape of the pattern.

- Casting Removal: The mold is broken or removed to extract the casted part.

Sand casting is cost-effective, suitable for large and complex parts, and allows for a wide range of materials.

However, the quality of sand castings can vary greatly depending on several factors, including the quality of raw materials, the casting process used, and the expertise of the manufacturer.

Why Choose China for Sand Castings?

China has become a dominant player in the global sand casting market for several compelling reasons:

- Cost-Effective Production: China’s lower labor costs and access to raw materials make it an attractive destination for cost-effective sand casting production.

- Diverse Manufacturing Capability: Chinese manufacturers can produce a wide variety of sand castings, from small, intricate parts to large, heavy-duty components.

- Advanced Technology: Many Chinese foundries have invested in modern equipment and technology, ensuring high-quality castings.

- Large Supplier Base: China boasts a vast network of foundries and suppliers, providing buyers with numerous options.

- Global Exporter: Chinese manufacturers are experienced in exporting, ensuring that products can be shipped to virtually any location worldwide.

Factors to Consider When Buying Sand Castings from China

Buying sand castings from China can be a fruitful endeavor, but it’s crucial to consider several factors to ensure a successful transaction:

- Quality Assurance: Quality is paramount. Ensure that the manufacturer has robust quality control processes in place. Look for certifications such as ISO 9001, which indicate a commitment to quality management.

- Material Selection: Discuss the material options available. Make sure the chosen material aligns with your project’s requirements in terms of strength, durability, and corrosion resistance.

- Production Capacity: Evaluate the manufacturer’s production capacity. Can they handle your order volume within your desired timeframe?

- Lead Times: Understand the lead times involved in production and shipping. Delays can disrupt your project schedule, so it’s essential to have a clear timeline.

- Communication: Effective communication is critical. Ensure that you can communicate with the manufacturer easily, and they understand your specifications and requirements.

- Samples and Prototypes: Request samples or prototypes before placing a large order. This allows you to assess the quality and suitability of the castings for your application.

- Cost and Pricing Structure: Discuss pricing in detail. Understand the breakdown of costs, including tooling, materials, labor, and shipping. Be cautious of significantly lower prices, as they may indicate subpar quality.

- Shipping and Logistics: Consider shipping costs, packaging, and logistics. China is a global exporter, so there are various shipping options available.

- Intellectual Property Protection: If your design or product is unique, discuss intellectual property protection with the manufacturer to prevent unauthorized replication.

- Payment Terms: Agree on payment terms that are mutually beneficial and secure. Be cautious of manufacturers demanding large upfront payments.

- References and Reviews: Request references or read reviews from previous clients. This can provide valuable insights into the manufacturer’s track record.

- Environmental Compliance: Inquire about the manufacturer’s environmental practices. Compliance with environmental regulations is essential, especially for certain industries.

Finding the Right Manufacturer

To find the right sand casting manufacturer in China, consider these strategies:

- Online Directories: Use online directories and B2B platforms to search for Chinese sand casting manufacturers. Websites like Alibaba, Made-in-China, and Global Sources are valuable resources.

- Trade Shows and Exhibitions: Attend industry-specific trade shows and exhibitions in China. This allows you to meet manufacturers in person and assess their capabilities.

- Agent or Sourcing Company: Consider working with a local agent or sourcing company in China. They can help you navigate the market, verify suppliers, and assist with quality control.

- Supplier Audits: Conduct supplier audits to evaluate a manufacturer’s capabilities, quality control processes, and facilities.

- Word of Mouth: Seek recommendations from industry peers who have experience sourcing sand castings from China.

- Verify Credentials: Ensure that the manufacturer has all the necessary licenses, certifications, and compliance with Chinese regulations.

- Visit the Manufacturer: If possible, visit the manufacturer’s facility to get a firsthand look at their operations and capabilities.

Quality Control and Inspection

Maintaining stringent quality control is crucial when sourcing sand castings from China. Here are some key steps in the quality control and inspection process:

- Initial Sample Inspection: Inspect the initial samples or prototypes thoroughly to ensure they meet your specifications and quality standards.

- In-Process Inspection: Establish a process for ongoing inspection during production. This helps identify and rectify issues early in the manufacturing process.

- Final Inspection: Conduct a final inspection before shipping. This should include dimensional checks, material composition tests, and visual inspections for defects.

- Third-Party Inspection: Consider hiring a third-party inspection agency to perform independent quality assessments.

- Packaging Inspection: Inspect the packaging to ensure that the castings are adequately protected during transit.

- Documentation Review: Verify all documentation, including certificates of compliance, test reports, and shipping documents.

Overcoming Language and Cultural Barriers

Effective communication is key when dealing with Chinese manufacturers.

Language and cultural differences can pose challenges, but they can be overcome with these strategies:

- Translator or Interpreter: Hire a translator or interpreter fluent in both Chinese and your native language to facilitate communication.

- Clear Specifications: Provide detailed and clear specifications in writing. Use drawings, diagrams, and technical documents to convey your requirements.

- Cultural Sensitivity: Be culturally sensitive and patient in your interactions. Understanding Chinese business customs and etiquette can help build better relationships.

- Regular Updates: Establish a system for regular updates and progress reports to ensure both parties are on the same page.

Navigating Shipping and Importing

Shipping and importing goods from China can be a complex process. Here are some considerations:

- Incoterms: Define the Incoterms (International Commercial Terms) that specify the responsibilities of the buyer and seller regarding shipping and delivery.

- Shipping Method: Choose the most suitable shipping method based on factors like cost, transit time, and the nature of your products.

- Customs and Duties: Understand the customs and import duties applicable in your country. Consult with customs authorities or a customs broker for guidance.

- Documentation: Ensure all required documentation, including invoices, bills of lading, and customs declarations, are accurate and complete.

- Packaging: Proper packaging is critical to prevent damage during transit. Work with the manufacturer to ensure adequate packaging.

Dealing with Challenges

While sourcing sand castings from China can be lucrative, challenges may arise.

Here’s how to address common issues:

- Quality Issues: If you receive subpar products, communicate with the manufacturer immediately to rectify the situation. Enforce your quality control agreements and contracts.

- Delays: Delays can disrupt your project. Monitor production progress closely and establish contingency plans if timelines are at risk.

- Communication Problems: Address communication issues promptly. Use clear and concise written communication to avoid misunderstandings.

- Legal Recourse: If disputes cannot be resolved amicably, consult with legal experts in both China and your home country to explore legal recourse.

- Intellectual Property Concerns: Protect your intellectual property with legal agreements and, if necessary, patents or trademarks.

Conclusion

Sourcing sand castings from China offers numerous advantages, including cost-effectiveness, diverse manufacturing capabilities, and access to a vast supplier base.

However, it’s essential to navigate this complex market with due diligence.

By carefully selecting the right manufacturer, maintaining stringent quality control, and effectively managing logistics, you can tap into the benefits of China’s sand casting industry while minimizing risks.

Remember that successful partnerships are built on clear communication, mutual trust, and a commitment to quality.

Beenyou Sand Casting: A Trusted Name in Quality Casting Solutions

When it comes to the world of sand casting, finding a reliable and experienced manufacturer is crucial.

Among the many players in this industry, Beenyou Sand Casting stands out as a trusted name known for its commitment to quality and innovation.

With a rich history and a reputation for excellence, Beenyou Sand Casting has become a go-to choice for businesses seeking top-notch casting solutions.

History and Expertise

Beenyou Sand Casting has a strong foundation in the sand casting industry.

Established several decades ago, the company has grown steadily to become a leader in the field.

This extensive experience brings a wealth of knowledge and expertise to every project they undertake.

Over the years, Beenyou Sand Casting has continuously invested in refining its casting processes and adopting cutting-edge technologies.

This commitment to staying at the forefront of industry advancements ensures that their clients benefit from the best possible casting solutions.

Diverse Product Range

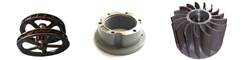

One of the key strengths of Beenyou Sand Casting is its ability to produce a wide range of sand castings to meet diverse customer needs.

Whether you require small and intricate components or large, heavy-duty parts, they have the capability to deliver. Their extensive product portfolio includes:

- Automotive Castings: Beenyou Sand Casting supplies critical components for the automotive industry. From engine parts to transmission components, their precision and attention to detail are highly regarded.

- Aerospace Castings: The aerospace sector demands the highest standards of quality and performance. Beenyou Sand Casting meets these demands by producing aerospace castings that meet strict industry requirements.

- Industrial Castings: From pumps and valves to machinery parts, they offer a comprehensive range of industrial castings that are durable and built to last.

- Custom Castings: If you have unique specifications or designs, Beenyou Sand Casting has the capability to create custom castings tailored to your exact requirements. Their experienced team works closely with clients to turn their ideas into reality.

Quality Assurance

Quality is at the core of Beenyou Sand Casting’s philosophy.

They understand that the performance and longevity of sand castings are paramount for their customers.

To ensure top-notch quality, they implement rigorous quality control measures throughout the casting process. These include:

- Material Selection: Beenyou Sand Casting uses high-quality materials to ensure the durability and reliability of their castings.

- Advanced Technology: They employ state-of-the-art technology and machinery to achieve precise and consistent results.

- Skilled Workforce: Their team consists of experienced and skilled professionals who are dedicated to delivering excellence.

- Quality Testing: Every casting undergoes thorough testing and inspection to verify its compliance with industry standards and customer specifications.

Global Reach

While based in China, Beenyou Sand Casting has a global reach. They have extensive experience in exporting their products to various international markets.

This global perspective allows them to understand and meet the unique needs and regulations of customers from different parts of the world.

Customer-Centric Approach

One of the reasons behind Beenyou Sand Casting’s success is its customer-centric approach.

They prioritize building strong and lasting relationships with their clients. This approach involves:

- Effective Communication: They believe in open and transparent communication throughout the project lifecycle, ensuring that clients are kept informed at every stage.

- Tailored Solutions: Beenyou Sand Casting understands that each project is unique. They work closely with clients to customize solutions that align with specific requirements and goals.

- Timely Delivery: Meeting deadlines is a priority for them. They understand the importance of timely delivery for their client’s projects.

- Responsive Support: In case of any questions or concerns, their responsive customer support team is always ready to assist.

Conclusion

Beenyou Sand Casting has earned its reputation as a trusted provider of quality sand castings through decades of dedication to excellence.

With a diverse product range, a commitment to quality assurance, and a customer-centric approach, they have become a preferred choice for businesses seeking reliable casting solutions.

Whether you’re in the automotive, aerospace, or industrial sector, or you have unique casting needs, Beenyou Sand Casting is poised to meet and exceed your expectations.