Your Reliable Manufacturer For

Sand Casting and Iron Casting

For the past 25 years Beenyou Casting only do one thing that is produce Sand Casting and Iron Casting. If you need any Sand Casting and Iron Casting for your business, you’ve come to the right place! Owing to our vast experience in the Sand Casting and Iron Casting domain,with the valuable assistance of creative casting team of our professionals, Beenyou engaged in manufacturing and supplying a wide range of Sand Casting and Iron Casting.

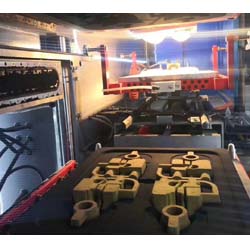

Feature Products

Check All Products

Beenyou Casting design & manufacture Sand Casting and Iron Casting.

Why Beenyou Exported

30+ Countries

- Beenyou Casting has 30 + Years of Iron Casting Products Manufacturing Experiences.

- Beenyou Casting can provide 5 Years of Output Warranty Services.

- Full support on your customized requirement on All kinds of Iron Castings

- Satisfied any Customized Technical Requirements on Iron Casting.

- All Team Support on you Any Order of Casting Products with Tight Deadline

How We Control Quality

Request A Quote

Beenyou Casting owns world-class laboratories which align with CE

Typical Applications on All Iron Castings

Keep us update on latest news on Iron & Sand Castings

Commonly Asked in Some Context

How to choose the best iron castings supplier in China?

1.Your iron castings supplier should be able to supply the high quality iron castings materials. 2. Your iron castings supplier should provide the testing report for all the iron castings. 3. Your iron castings supplier should provide the best iron castings solutions for your projects. 4. Your iron castings supplier should provide competitive rates and a very good service. 5. Your iron castings and clay sand casting supplier should provide other services such as technical support and iron castings services. Even the container loading preparation, freight cost inquiry and arrangement, etc.

How to control quality of iron castings in your factory?

1.We have more than 5 procedures of testing and inspection on the iron castings. 2. We inspect the appearance on the iron castings since we bought materials from our cooperate iron castings manufacturers. And also we do Testing on all the iron castings. 3. We do inspection on all the iron castings items before delivery..

How to get your sand casting project ready from our factory?

1. Evaluate Your drawings per project or order. 2. Decide and quote the right price on your sand castings drawing. 3. Size Your Complete sand castings according to your specific drawing. 4.Let Us design and manufacture Your sand casting order.

How to know more about sand castings?

We wrote blogs from our website, and will update more information on sand castings, iron castings, clay sand castings, and more news also for investment castings, visit our website and you will know more on the castings products.

How to choose the best sand castings supplier in China?

1. Your sand castings supplier should keep good smoothly communicate with you. Get your requirements, know your ideas aboutsand castings. And give you quick quote. 2. Your sand castings supplier should be able to design and guide you choose the most suitable size for your sand castings. 3. Your sand castings supplier should provide competitive rates and a good service. They should supervise purchasing and production and make on time delivery.4. Your sand castings supplier should provide the best shipping solution possible.5. Your sand castings supplier should provide technical support and after sale service.

How to get quote from your sand castings factory?

Beenyou casting make and export sand castings, steel metal castings for customers. if you are buying sand castings, steel metal castings, clay sand castings for your customer of your own drawing, kindly contact for a quote.

.

.

How to order from you, do you provide free samples?

We have our own sand casting factory near Shanghai in China. You can come to visit our sand castings production line and come to visit our factory. Send us your purchase order of sand castings with the right drawing and quantities, we will issue the Proforma Invoice for you to pay. After we get the first deposit ,we start to manufacture the sand castings order, or the steel metal castingss, investment castings. We don’t provide free samples. .

Do you accept custom design on sand castings?

We can make customer design for sand casting on sizes. Our 36 R&D staffs can make sure to provide best casting solutions for your castings kits. We have our castings project engineer track your order and give professional training on how to use our sand castings.